Product Description

Custom High Precision Nested Wave Springs with Shim Ends Wave pad manufacturers

Description:

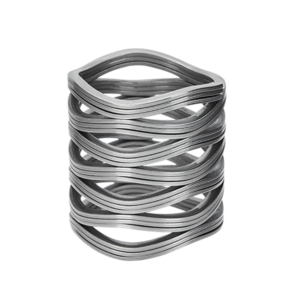

- A wave spring, also known as a coiled wave washer spring or microwave spring, is a spring made up of pre-hardened flat wire in a process called on-edge coiling (also known as edge-winding). During this process, waves are added to give it a spring effect.

- MultiWave springs should be used for all applications requiring tight load deflection specifications where axial space is critical.

- Capabilities: Spring thickness from 0.15mm to 0.7mm (0.006¡±to 0.0276¡±)

- Spring outside dia. from 12mm to 60mm(0.472¡±to 2.36¡±)

Please offer me your drawing or sample, so we can produce it according to your request.

Spring wave washer anti-loose principle

The anti-loosening principle of the spring wave washer is that after being flattened, the spring wave washer will generate a continuous elastic force, so that the threaded connection pair between the nut and the bolt will continue to maintain a frictional force, generating a resistance torque to prevent the nut from loosening. At the same time, the sharp corners at the opening of the spring wave washer are respectively embedded in the surface of the bolt and the connected part, thereby preventing the bolt from rotating relative to the connected part.

The main function of the spring wave washer is to protect the surface of the connector and prevent the surface of the workpiece from being scratched when the bolt and nut are tightened; the spring wave washer is anti-loose. However, for some important connections, such as places that rely mainly on compression to generate frictional force to transmit power, spring pads cannot be used, and the rigidity of the connection is reduced, which is prone to accidents.

The basic function of the spring wave washer is to give a force after the screw and bolt are tightened to prevent loosening. Increase the friction force between the screw bolt and the material, so that the material tightens the material in the vibration and prevents the loosening between the screw bolt and the material. Simply put, the role of the spring washer is to play the role of a protective measure.

The difference between flat washers and spring wave washers

The elasticity of the ordinary spring washer is relatively large, and the anti-loosening effect is obvious and reliable by virtue of its large elastic force and the frictional force of the oblique opening. It is used for the anti-loosening occasion of the mechanical structure of the channel. The wave spring washer presses the connected parts by its elastic deformation to prevent loosening, The wave washer has a small elastic force, and the force is uniform, and the surface of the connected parts is not damaged. It is usually dedicated to occasions where general anti-loosening is required. For example, this type of washer is used to prevent the link between the two blades of hair clippers from loosening.

Flat washers are generally used to increase the contact area between parts. Its principle is not only to reduce the damage of parts by increasing the contact area between parts but also to reduce the pressure between the nut and the equipment. It is an umbrella-like existence. Since the flat washer has no buffer, it cannot act as a shock absorber. In addition, compared with the spring washer, the flat washer has no anti-loosening function. The spring wave washer is different. The spring washer can play a good anti-loosening and anti-seismic effect according to its own elastic advantages.

When the strength of the connected parts is low, use flat washers or flange bolts to increase the contact area. When there is vibration, pulse, and large fluctuations in the temperature of the medium, spring wave washers must be used. The spring wave washer can increase the preload and prevent loosening, while the flat washer does not. However, due to the influence of material processes and other factors, the spring wave washer will break. Even so, some important connections, such as places that rely mainly on compression to generate frictional force to transmit power, cannot use spring pads, which reduce the rigidity of the connection and are prone to accidents.

Factors to consider when choosing a wave washer

Wave washers are mechanical devices that are used to provide a preload on a fastener or to maintain the position of a component. When choosing a wave washer, the following factors should be considered:

- Material: Wave washers are typically made of spring steel, stainless steel, or other durable materials. You should choose a material that is compatible with the application, and that can withstand the environmental conditions in which the washer will be used.

- Load capacity: The washer must be able to withstand the forces that will be exerted on it during normal operation.

- Corrosion resistance: If the washer is used in an environment where corrosion is a concern, it should be made of a material that is resistant to rust and other forms of corrosion.

- Temperature range: The washer should be able to operate within the temperature range of the application.

- Inner and outer diameter: The inner and outer diameters of the washer should match the dimensions of the fastener or component on which it will be used.

- Wave height and number of waves: The wave height and number of waves will affect the force produced by the washer. Choose the one that fits your application’s needs

- Brand reputation: It is always a good idea to consider the reputation of the manufacturer when choosing a wave washer, so you can be sure you are getting a quality product that meets your needs.

- Compliance: It is important to check if the wave washer is compliant with any relevant industry standards or regulations, such as those set by ASTM, ASME, or ANSI.

By considering these factors, you can be sure to select a wave washer that is well-suited to your application and will provide reliable performance over time.

Why Choose Us?

- Industrial experience

We specialized in the wave spring field since the year of 2009.

- Sample availability

We can send samples for your approval within 7 days; Free of charge if we have an available tool.

- Quickly Delivery

As usual within 7 days.

- Good service and best quality

Our business belief is “best competitive price, good service, and best quality”

Good Service:

We will respond to you within 24 hours. We can manufacture nonstandard parts according to your drawings. As a professional China wave washer company, we will provide you with the best after-sales service.

Low Price:

The price of our products is reasonable and competitive than other manufacturers.

Rich Experience:

We have been engaged in the wave washer springs for 11 years. Our company has a good reputation with customers from America, Europe and Australia, etc. We also have a good team for sales and quality control.

In the world of engineering and mechanical assemblies, achieving precision, reliability, and longevity is paramount. One often-overlooked component that plays a critical role in these aspects is the humble yet indispensable wave washer. This unassuming yet highly functional hardware device has found its way into a multitude of applications across various industries, from automotive and aerospace to electronics and manufacturing.

In this comprehensive product description, we will explore the myriad benefits and applications of wave washers, shedding light on how this unassuming component can make a significant difference in your engineering endeavors.

Understanding Wave Washers

Wave spring washers, also known as wave spring washers, exhibit a distinctive design characterized by their wave-like or corrugated shape. This design imparts them with unique mechanical properties, making them indispensable for various tasks where flexibility, preload, shock absorption, or vibration damping are essential.

The Science Behind the Wave Washer

Wave washers derive their exceptional functionality from their inherent spring-like action. When compressed axially, their wave-like structure allows them to flex and deform, generating a force that can be harnessed for specific purposes. This force can provide preload to maintain tightness in an assembly, compensate for thermal expansion, or absorb shocks and vibrations.

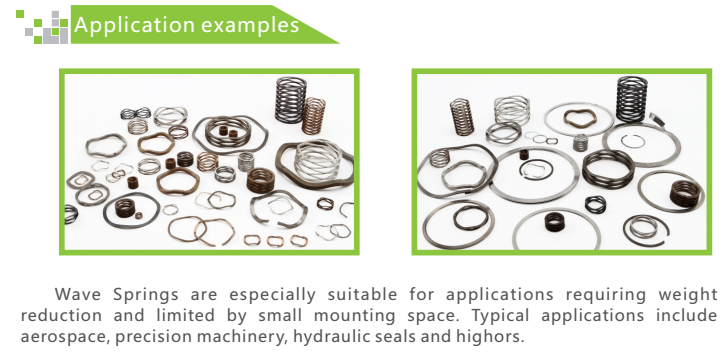

Applications of Wave Spring Washers

Wave spring washers find themselves at home in a wide array of applications across multiple industries. Below, we delve into some of the key sectors where wave washers play a pivotal role:

- Automotive Industry: In the automotive sector, wave washers are frequently used in suspensions, braking systems, and transmissions. Their ability to absorb shocks and reduce vibrations ensures a smoother and safer ride. Wave washers also help maintain the integrity of critical components in harsh automotive environments.

- Electronics and Electrical Engineering: In the electronics industry, wave washers are crucial for ensuring reliable electrical connections. They are often employed in connectors, switches, and circuit boards, where their spring-like action guarantees consistent electrical contact, even in high-vibration environments.

- Machinery and Manufacturing: Wave washers are indispensable in machinery and manufacturing assemblies, where precision and tightness are paramount. They are found in gearboxes, couplings, and various other mechanical systems, ensuring the integrity of critical components and reducing the risk of loosening due to vibrations.

- Aerospace and Defense: In the aerospace and defense sectors, reliability and performance are non-negotiable. Wave washers are used in a wide range of applications, from aircraft landing gear to missile systems. Their ability to withstand extreme conditions and maintain structural integrity makes them a staple in these industries.

- Medical Devices: The medical industry relies on wave washers for applications where precise preload and shock absorption are essential. From surgical instruments to diagnostic equipment, wave washers ensure the reliability and longevity of critical medical devices.

Types of Wave Washers

Wave washers come in various types, each tailored to specific applications and performance requirements:

- Single Wave Spring Washers: These are the most common type of wave washers, featuring a single wave-like structure. They provide a moderate amount of axial flexibility and are suitable for a wide range of applications.

- Multi-Wave Washers: Multi-wave spring washers feature multiple waves, offering increased axial deflection and higher spring rates. This makes them ideal for applications requiring greater preload or shock absorption capabilities.

- Curved Washers: Curved washers, as the name suggests, have a curved shape that allows them to distribute loads more evenly. They are often used in applications where flat washers would not suffice.

Materials and Customization

Wave washers are typically manufactured from materials such as spring steel, stainless steel, and even plastics. The choice of material depends on the specific application’s requirements and the environmental conditions in which the wave washer will operate.

Manufacturers often offer customization options, allowing engineers to tailor wave washers to their precise needs. Customization can include adjustments to the number of waves, wave height, material thickness, and outer diameter, ensuring that the wave spring washer perfectly complements the intended application.

Installation and Maintenance

Proper installation of wave washers is crucial to maximize their effectiveness. Manufacturers provide guidelines on installation procedures and torque values to ensure that the wave spring washer functions as intended. Regular maintenance involves inspecting wave washers for wear, damage, or deformation and replacing them promptly if any issues are detected.

Conclusion

In the intricate world of engineering and mechanical design, every component plays a vital role in achieving optimal performance, reliability, and longevity. Wave washers, with their unique wave-like design and spring-like action, stand as silent sentinels in countless applications across diverse industries. From absorbing shocks and vibrations in automotive suspensions to maintaining electrical connections in advanced electronics, wave spring washers are the unsung heroes of engineering assemblies.

Whether you are a seasoned engineer seeking to enhance the performance of your machinery or a designer aiming to ensure the reliability of your medical device, wave washers have a role to play. Their versatility, coupled with the ability to customize them to precise requirements, makes them an invaluable asset in achieving engineering excellence.

In your quest for precision, reliability, and performance, don’t underestimate the power of the wave washer. Embrace this unassuming yet indispensable component, and watch as it transforms your engineering endeavors into feats of ingenuity and dependability.