SKU

c3f3d1e9b736

Categories Wave Spring, Wave Spring Washer

Tags spiral retaining ring, wave rings, wave spring

Product Description

Round Section Wire Wave Spring Circular, Wave Circle Ripple Spring Coil

Description:

Round-section wire wave rings springs are produced from round-section wire to provide higher loads while maintaining the accurate loading found in wave rings springs. As an alternative to Belleville Springs, the round-section wire wave spring provides similar loads but with an accurate, predictable spring rate.

Round-section wire wave springs are a type of wave spring that offers a number of advantages over other types of wave ring springs. They are available in a wide range of sizes, making them a good choice for a variety of applications. Additionally, they are very strong and can withstand a great deal of pressure without becoming damaged.

What is a round-section wire wave ring spring?

Round-section wire wave springs are a type of compression spring that can be found in a variety of applications. They are typically made from stainless steel, although other materials may be used. Round-section wire wave springs are characterized by their wave-like profile, which allows them to compress and rebound easily. This makes them ideal for use in applications where a high level of elasticity and resilience is required.

What are the benefits of using round-section wire wave springs?

Round-section wire wave springs are slowly gaining in popularity due to their many benefits. Some of these benefits include:

They are easier to manufacture than traditional wave springs.

They are more compact than traditional wave springs, making them ideal for use in tight spaces.

They are more durable than traditional wave springs, making them ideal for use in harsh environments.

– They are more resistant to fatigue than traditional wave springs, making them ideal for use in repetitive applications.

How do you select the right round-section wire wave spring for your application?

There are many factors to consider when selecting the right round-section wire wave ring spring for your application. The first decision you’ll need to make is the size of the spring. You’ll also need to decide on the material, the number of coils, and the wire diameter.

Once you have these basics figured out, you’ll need to determine the load that the spring will need to support and the type of environment it will be used in. The spring’s temperature range and the amount of deflection it will need to provide are also important factors to consider.

With all of this information in hand, you can then select the right round-section wire wave spring for your application.

How do you maintain a round-section wire wave spring?

To keep your round section wire wave rings spring in good condition, you should follow these tips:

– Keep the spring clean and dry.

– Avoid contact with oils and other chemicals.

– Store the spring in a cool, dry place.

If you are looking for a quality wave spring that can handle a lot of pressure, a round-section wire wave spring is a good choice. They are available in a variety of sizes so you can find the perfect size for your application. Also, they are very strong and can withstand a lot of pressure without damage. If you need customization, please feel free to contact Lisheng Spring. We are a professional alloy multi-turn wave springs company, you can trust the quality of our products.

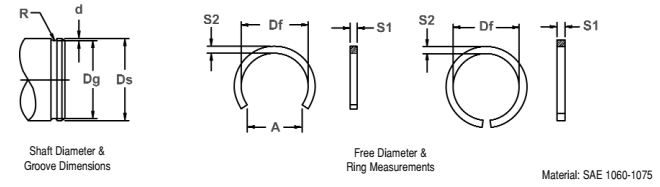

Specification:

| Material |

OIL TEMPERED (SAE1070-1090), HARD DRAWN SAE 1060 – 1075, stainless steel 304,316,631,17-7PH (SUS), beryllium copper, phosphor copper, 65Mn, A-286, Inconel Alloy X-750, X-718, Elgiloy, MONEL K-500, MONEL 400 etc |

| Processing Steps | Design →Drawing→ Flat the wire → CNC Machining → Heat treatment → Surface → Finishing →Quality Inspection → Packing |

| Finish | Oil Dip, passivation, blacking, zinc/nickel/chrome/silver/gold plating, powder coated, etc |

| Applications | For aerospace, automotive, medical, off-highway, oil & gas, Wind power, Consumer Industrial |

|

Primary Competitive Advantage |

?Over 3000 types of Wave springs and Spiral rings standard parts in stock ?Service Sample Available ?We have over 10 years of professional experience as a manufacturer of Wave springs, Spiral Retaining Rings, Constant Section Retaining Ring, Laminar Seal Rings |

Wave spring measurements:

Introduction

Wave rings are a captivating and symbolic form of jewelry that has gained popularity in recent years. Their unique design, often inspired by the mesmerizing patterns of ocean waves, evokes a sense of calm and the beauty of nature. These rings serve not only as aesthetically pleasing accessories but also as meaningful symbols of the wearer’s connection to the natural world and the ebb and flow of life’s experiences. In this comprehensive article, we will explore the origins, designs, symbolism, and popular uses of wave rings, shedding light on what makes them a timeless and fascinating choice for jewelry enthusiasts.

I. Origins of Wave Rings

Wave rings draw inspiration from the natural world, particularly the intricate patterns created by ocean waves. While their exact origins are difficult to pinpoint, the use of wave-like motifs in jewelry can be traced back to various cultures throughout history. These motifs have been used to represent water, life, and the cyclical nature of existence.

- Ancient Symbolism: Waves have been a symbol of life, renewal, and eternity in numerous ancient cultures. For example, in ancient Egypt, the Nile River’s annual flooding, symbolized by waves, brought life-sustaining waters to the region. Similarly, in ancient China, waves symbolized eternal life and good fortune.

- Japanese Influence: The concept of waves holds particular significance in Japanese culture. The country’s artistic tradition includes depictions of waves as symbols of strength and resilience. The famous woodblock print “The Great Wave off Kanagawa” by Hokusai, part of the “Thirty-Six Views of Mount Fuji” series, is a prominent example of wave imagery that has influenced art and jewelry design.

- Modern Wave Rings: In recent times, jewelry designers and craftsmen have reimagined these age-old symbols, creating wave rings that capture the beauty of the natural world. The modern wave ring has gained popularity for its aesthetic appeal and meaningful symbolism.

II. Design Variations of Wave Rings

Wave rings come in a variety of designs, offering wearers the freedom to choose a style that resonates with their personal preferences and the meaning they wish to convey. The following are some popular design variations:

- Sculpted Wave Rings: These wave rings are crafted with three-dimensional, sculpted waves that wrap around the finger. They often have a more substantial and intricate design, creating a visually striking and realistic representation of waves.

- Simple Band Wave Rings: For those who prefer a more understated look, simple band wave rings feature a continuous wave pattern engraved or etched onto a smooth metal band. These rings are elegant and versatile, making them suitable for everyday wear.

- Wave and Gemstone Rings: Some wave rings incorporate gemstones to represent various elements of the ocean, such as the deep blue sea or the sparkle of sunlight on the water. Blue sapphires, aquamarines, and opals are popular choices for these designs.

- Customized Wave Rings: Many jewelers offer customization options, allowing customers to personalize their wave rings with engravings, specific materials, or gemstones. Customized wave rings make for meaningful gifts or cherished mementos.

III. Symbolism of Wave Rings

Wave rings carry a wealth of symbolism, and their meaning can vary depending on individual interpretation and cultural context. Some of the most common symbolic associations include:

- Resilience: Waves are often seen as symbols of resilience and strength. Just as waves continue to crash against the shore, individuals wearing wave rings may find inspiration in the idea of overcoming challenges and obstacles with determination.

- Change and Transformation: The cyclical nature of waves, constantly changing from high to low tides, mirrors the ebb and flow of life’s experiences. Wave rings can serve as reminders of the impermanence of life and the need to adapt to change.

- Connection to Nature: Wave rings establish a connection between the wearer and the natural world, reminding us of the beauty and power of the ocean. For those who have a deep affinity for the sea, these rings can be powerful symbols of that connection.

- Adventure and Exploration: Waves also represent adventure, exploration, and the vastness of the world’s oceans. Wave rings are favored by individuals who love to travel and seek new horizons.

- Emotional Balance: The gentle rhythm of waves can evoke a sense of emotional balance and tranquility. Wearing a wave ring may remind the wearer to seek peace and calmness in their daily life.

IV. Popular Uses of Wave Rings

Wave rings have found popularity in a wide range of contexts, including fashion, commitment, and symbolism. Here are some of the popular uses of wave rings:

- Engagement and Wedding Rings: Many couples choose wave-inspired engagement and wedding rings to symbolize the ever-changing yet enduring nature of their love.

- Fashion Statements: Wave rings are worn as fashion accessories that complement various outfits and styles. Their aesthetic appeal and symbolism make them a favorite choice for everyday wear.

- Gifts: Wave rings make thoughtful and meaningful gifts for loved ones. They can be given to mark special occasions or simply to convey a message of support, strength, or love.

- Travel Souvenirs: Travelers often purchase wave rings as souvenirs to remind them of their adventures and explorations near the sea.

- Spiritual and Mindful Jewelry: Some individuals wear wave rings as part of their spiritual or mindful practices, finding inspiration and serenity in the symbolism of waves.

Wave rings offer a captivating blend of natural beauty, deep symbolism, and artistic expression. As a form of jewelry inspired by the mesmerizing patterns of ocean waves, these rings have the power to resonate with wearers on multiple levels. Whether you are drawn to their aesthetic allure, their symbolism of resilience and change, or their representation of the vast and wondrous natural world, wave rings continue to captivate the hearts and minds of jewelry enthusiasts, making them a cherished and timeless choice in the world of jewelry.

FAQs

Q: What are wave rings?

Wave rings are a type of jewelry that feature designs inspired by the patterns and shapes of ocean waves. They are typically rings that can be worn on the fingers and come in various designs, each representing the beauty and symbolism of waves.

Q: What is the symbolism associated with wave rings?

Wave rings often symbolize concepts such as resilience, change, and the cyclical nature of life’s experiences. They can also represent a connection to nature, emotional balance, and a sense of adventure and exploration.

Q: How do wave rings come in different designs?

Wave rings come in various design variations. They can have sculpted three-dimensional waves, simple band designs with wave engravings, or even include gemstones to represent elements of the ocean. Some jewelers offer customization options for personalized wave ring designs.

Q: What occasions are wave rings typically worn for?

Wave rings are versatile and can be worn for various occasions. They are often chosen for engagement and wedding rings to symbolize enduring love. They are also popular as fashion accessories, everyday wear, and as gifts for special occasions or travel souvenirs.

Q: Can wave rings be customized or personalized?

Many jewelers offer customization options for wave rings. Customers can personalize their rings with engravings, specific materials, or gemstones to make them unique and meaningful.

Q: What materials are wave rings typically made from?

Wave rings can be made from various materials, including precious metals like gold and silver, and may incorporate gemstones. The choice of material often depends on the wearer’s preferences and budget.

Q: Are there specific cultural or historical influences on the popularity of wave rings?

Wave motifs have been used in various cultures throughout history to symbolize elements like water, life, and eternity. In Japanese culture, wave symbolism is particularly significant, and it has influenced wave ring designs.

Q: Are there specific maintenance considerations for wave rings?

Maintaining wave rings is similar to caring for other types of jewelry. They should be cleaned regularly to remove dirt and grime, and any gemstones or materials used should be handled and stored appropriately to prevent damage.

Q: How can I choose the right wave ring for myself or as a gift?

When choosing a wave spring, consider factors such as the design that resonates with you, the materials used, and the symbolism you wish to convey. Personalized options allow you to create a ring that holds special meaning.

Q: Where can I purchase wave rings, and how do I ensure their authenticity and quality?

Wave rings are available from jewelry retailers, both online and in physical stores. To ensure authenticity and quality, it’s important to purchase from reputable jewelers and request information about the materials and craftsmanship used in the ring. Look for customer reviews and ratings to gauge the jeweler’s reputation.