Wave springs have been around for centuries, but the recent development of overlap wave springs has led to renewed interest in these devices. Overlap wave springs offer a number of advantages over traditional wave springs, including reduced size and weight, increased flexibility, and improved performance. As a result, they are quickly becoming the wave of the future for a wide range of applications.

1. What are overlap wave springs?

1.1 What are overlap wave springs?

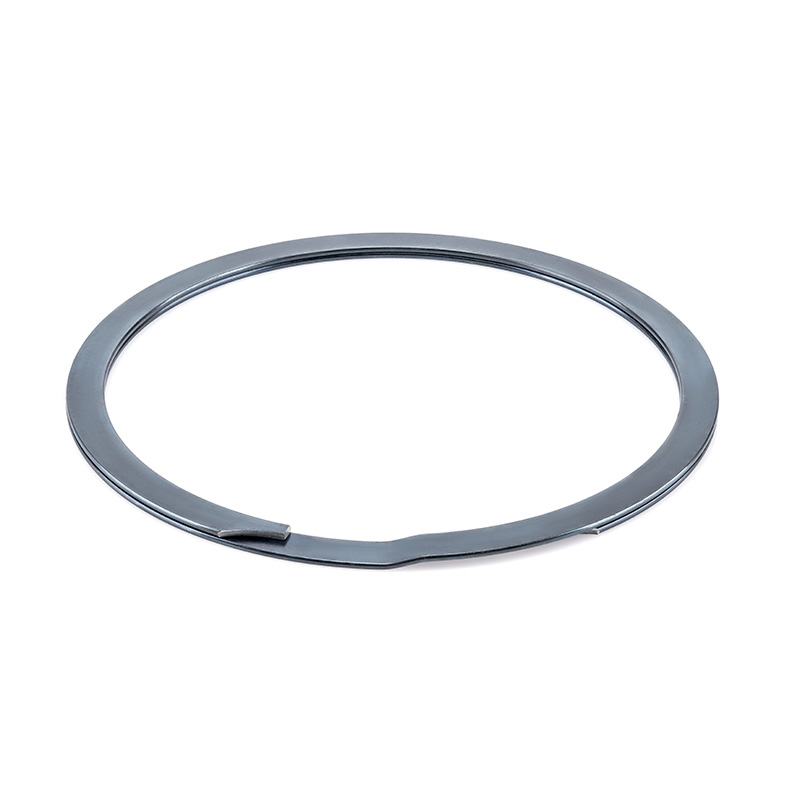

Overlap wave springs are a type of wave spring that has two or more coils that are overlapped. This type of spring is used to absorb shock and vibration. They are also used to maintain a consistent force over a range of motion.

1.2 How are overlap wave springs made?

Overlap wave springs are made by combining two or more wave springs together. The wave springs are placed on top of each other, and then they are welded together. This creates a spring that is thicker and has more overlap than a traditional wave spring.

1.3 What are the benefits of using overlap wave springs?

Wave springs are becoming a popular choice in a variety of industries because of their unique design and performance benefits. One of the most popular types of wave springs are overlap wave springs. Overlap wave springs are made up of two or more wave springs that are overlapped. This design allows for a larger spring area, which results in higher force and stiffness. Additionally, overlap wave springs are able to handle more load and are more resistant to fatigue than other wave spring designs. As a result, overlap wave springs are becoming a popular choice for a variety of applications.

1.4 What are the limitations of using overlap wave springs?

Overlap wave springs are a type of wave spring that uses two or more coils of wire to create a wave-like pattern. This type of spring has many advantages over traditional coil springs, including high deflection, low force, and low noise. However, there are some limitations to using overlap wave springs, including their limited range of motion and the need for a flat surface.

2. What are the benefits of using overlap wave springs?

2.1 Overlap wave springs offer a number of benefits over other types of springs.

Overlap wave springs offer a number of benefits over other types of springs. They are more compact and can provide more force than traditional coil springs. They are also less likely to buckle, making them ideal for applications where space is limited.

2.2 Their unique design allows them to handle high loads while maintaining a small footprint.

Overlap wave springs are a unique type of spring that have a number of benefits over traditional springs. Their design allows them to handle high loads while maintaining a small footprint, making them ideal for use in tight spaces. Additionally, they are very easy to install and can be used in a wide range of applications.

2.3 They are also very resilient, meaning they can return to their original shape after being compressed.

Overlap wave springs are unique in that they are able to provide both compression and tension forces. This makes them ideal for use in a variety of applications. They are also very resilient, meaning they can return to their original shape after being compressed.

2.4 This makes them ideal for use in a variety of applications.

Overlap wave springs are a type of wave spring that have two or more coils that overlap each other. This makes them ideal for use in a variety of applications, as they can provide a large amount of force in a small package. They are also very resistant to wear and tear, making them a popular choice for use in industrial applications.

3. Factors Affecting Spring Fatigue Strength

3.1 Yield strength There is a certain relationship between the yield strength of the material and the fatigue limit. Generally speaking, the higher the yield strength of the material, the higher the fatigue strength. Therefore, in order to improve the fatigue strength of the spring, we should try to increase the yield strength of the spring material. Or use a material with a high ratio of yield strength to tensile strength.

3.2 The maximum stress of the surface state mostly occurs on the surface of the spring material, so the surface quality of the spring has a great influence on the fatigue strength.

3.3 The larger the size of the size effect material, the higher the possibility of defects caused by various cold and hot working processes, and the greater the possibility of surface defects, all of which will lead to a decrease in fatigue performance.

3.4 Metallurgical defects Metallurgical defects refer to non-metallic inclusions, air bubbles, segregation of elements, etc. in the material. Inclusions present on the surface are stress concentrators that lead to premature fatigue cracks at the interface between the inclusions and the matrix. Measures such as vacuum smelting and vacuum pouring can greatly improve the quality of steel.

3.5 Corrosive medium When the spring works in a corrosive medium, it becomes a source of fatigue due to pitting corrosion on the surface or corrosion of the grain boundary on the surface, and it will gradually expand under the action of variable stress and cause fracture. The effect of corrosion on the fatigue strength of the spring is not only related to the number of times the spring is subjected to variable loads, but also to the working life.

3.6 The fatigue strength of carbon steel decreases from room temperature to 120°C, rises again from 120°C to 350°C, and decreases after the temperature is higher than 350°C. There is no fatigue limit at high temperatures. For springs working under high temperature conditions, heat-resistant steel should be considered. At temperatures below room temperature, the fatigue limit of steel increases.

Zhejiang Lisheng Spring Co., Ltd. is a professional gap wave spring supplier. We have advanced technology and excellent product quality. Our company is a component supplier for major national science and technology projects; our company has thousands of regular-sized product stocks. If you are interested in our products please contact us.