Using the correct spiral retaining ring material can avoid additional costs and mistakes in use. Carbon steel is the most common material. Although non-material steel is more expensive than carbon steel, it is far superior to carbon steel in terms of corrosion resistance and temperature resistance.

Carbon steel spiral retaining ring

Oil Tempered Carbon Steel (Oil Tempered)

SAE1070-1090 high carbon tempered spring steel is the standard material for spiral retaining rings and wave springs. Due to the oil tempered martensite structure treatment, the tensile strength and yield strength reach the maximum.

Cold drawn high carbon steel (Hard Drawn)

SAE1060-1075 high carbon cold drawn spring steel is the standard material for strong washers. Carbon steel will corrode without lubricating oil or in a closed environment. Special surface treatment can improve the corrosion resistance. Spiral retaining rings and springs are usually treated with oil for protection during transportation and storage.

Carbon steel spiral retaining ring has high magnetic properties and is available in blue, black and gray colors.

Stainless steel spiral retaining ring

302 Stainless Steel

302 stainless steel is the standard material for spring washers. This material has corrosion resistance and good physical properties, so it is widely used. Although 302 stainless steel is classified as non-magnetic, it is slightly magnetic due to its good toughness due to the cold working process. This material cannot be hardened by heat treatment. 302 stainless steel has a silver-gray appearance.

316 Stainless Steel

The physical properties and temperature resistance of 316 stainless steel are almost the same as those of 302, but its magnetism is weaker than that of 302, and it cannot be hardened by heat treatment. Because 316 contains molybdenum chemical composition, it has higher corrosion resistance, and is often used in food cooking utensils, chemical aspects, and application environments with seawater components. 316 stainless steel has a silver-gray appearance

17-7 PH/C Stainless Steel

It has similar corrosion resistance to 302, and is almost a special material for wave springs and spiral retaining ring. In the application of special washers, it has high tensile strength and yield strength. It outperforms the highest grades of carbon steel in terms of fatigue resistance and high stress. The spring property possessed by precipitation hardening from C to CH-900 state will not lose its properties even at a temperature of 343°C. 17-7 PH C/CH-900 has the magnetic properties similar to high carbon steel.

After precipitation hardening heat treatment outside the furnace, the appearance of 17-7 is blue, brown or silver. The appearance after heat treatment in the furnace is brighter.

Super alloys spiral retaining ring

Inconel X-750

Most of these chromium-nickel alloy steels are used in high temperature and corrosive environments. The following outlines two commonly used tempering methods for Inconel. Usually, Inconel X-750 is subjected to precipitation hardening heat treatment to achieve elastic tempering state. Under this condition, it can withstand high temperature up to 371°C, and its tempering hardness reaches the highest value of Rc50, which meets the National Association of Corrosion Technicians (NACE) MR-01 -75 accreditation criteria. (applicable to elastic washers, wave springs and compression springs).

Tempering, the heat treatment time is longer than elastic tempering, so the tensile strength is lower, but the temperature resistance can reach 538°C.

The heat treatment methods of elastic tempering and tempering are in-furnace or out-of-furnace heat treatment. Oxidation from out-of-furnace heat treatment usually results in a slight black residue. Furnace heat treatment avoids residues.

Inconel wave springs and spiral retaining ring treated in this way have a silver-gray or blue-gray appearance and are non-magnetic.

A286 alloy spiral retaining ring

This type of alloy spiral rataining ring material has similar properties and heat treatment methods as Inconel X-750, and its temperature resistance can reach 538°C. Non-magnetic, the appearance is silver-gray or blue-gray.

Elgiloy

It has excellent corrosion resistance and high temperature resistance, and is usually used in the petroleum industry. It has been proved by the anti-sulfide stress failure experiment of NACE; Elgiloy has higher reliability than other alloy materials. In addition, the temperature load capacity of the alloy material at 343°C is six times higher than that of 17-7, and its fatigue resistance is 100% better than that of ordinary carbon steel. Non-magnetic, the appearance is silver-gray or blue-gray due to heat treatment.

Coppers

#25 Beryllium Copper Alloy

This type of alloy steel combines the physical properties of low modulus of elasticity and high tensile strength through precipitation hardening heat treatment, so it has excellent elasticity. Compared to other copper alloys, beryllium copper alloy has the highest strength and retains its excellent physical properties at elevated temperatures. Non-magnetic, the conductivity is about 2 to 4 times that of phosphor bronze.

Phosphor Bronze, Grade A

It has moderate elasticity and conductivity, second only to beryllium copper alloy. The best spring properties of phosphor bronze are obtained in the elastic tempered state. Phosphor bronze is non-magnetic and can only be hardened by cold work.

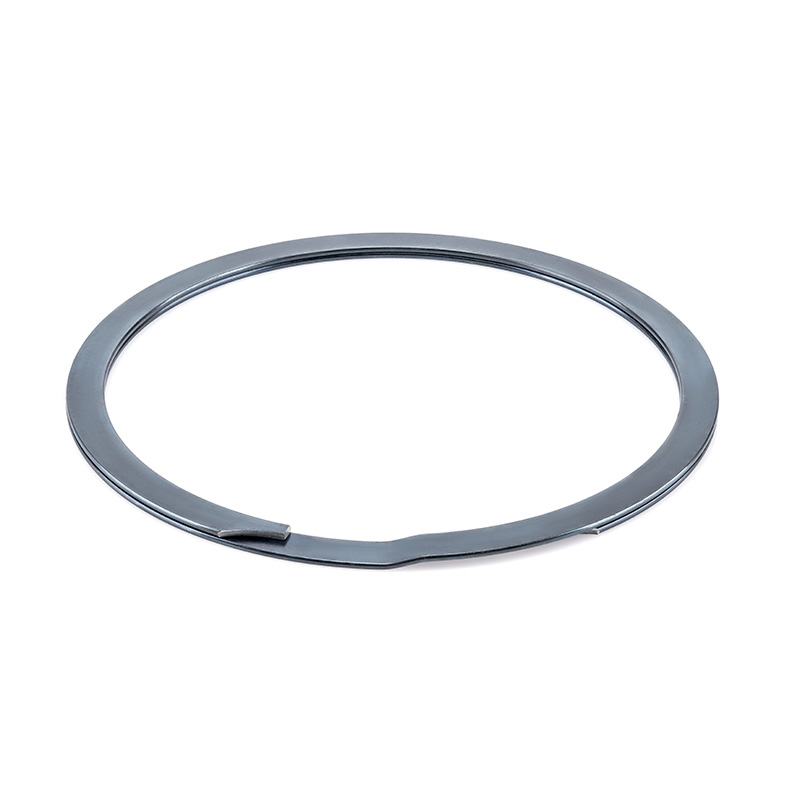

Zhejiang Lisheng Spring Co., Ltd. is a member enterprise of China Spring Association. We have rich production experience and excellent product quality. Our products mainly include single turn gap wave spring washer, round wire snap ring, laminar seal rings, etc. If you want to buy single turn wave spring, then please contact us. At present, our company has thousands of specifications of wave springs, we will provide you with the best service, and look forward to establishing a mutually beneficial and win-win cooperation relationship with you.