SKU

bf4a3c4ced72

Categories Hot product, Wave Spring, Wave Spring Washer

Tags overlap wave spring, wave spring, wave spring washer, wave washer

Product Description

Single turn wave disc springs wavy spring washers 17-7ph suppliers

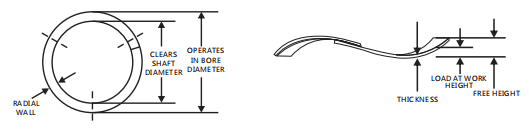

Single turn overlap wave springs are used for several applications, mainly designed for short deflection and low to medium forces. Technology enables to provide a dependable and accurate fit.

Overlap wave spring is a single turn wave spring with partial overlap at the fracture. Like other wave springs, overlap wave spring washer is also made of flat wire, and then undergoes different heat treatments and surface treatments to make it work in the corresponding working environment. It has good elasticity and toughness.

Traditional overlap wave springs are used in a variety of applications. They function precisely and reliably in applications with short deformation ranges and low to medium levels of force. The ends of the gap wave spring are separated with gaps between the ends; while the ends of the overlap wave spring overlap each other. This type of wave spring allows radial expansion or diameter increase within the cavity without the binding or hang-up typically associated with stamped wave washers. Overlapping types have overlapping ends so that the ends are free to move around the circumference as the outer diameter of the spring grows during compression.

Overlap wave spring is also called overlap wave washer. It is a single turn wave washer with partial overlap at the fracture. Like other wave springs, the overlap wave spring washer is also wound by flat wire, and then undergoes different heat treatments and surface treatments to make it has good elasticity and toughness in the corresponding working environment.

An overlap wave spring will have a higher solid height than a gap wave spring due to overlapping ends, which will prevent the springs from wrapping around each other in the package.

Overview of single turn overlap wave spring:

The single turn overlap wave spring of Lisheng Company is a wave washer punched by an automatic punching machine. It is a precision elastic gasket composed of multiple peaks and troughs. According to the current conditions of use and stress conditions, the company’s self-developed computer-aided design is adopted. The system can determine the geometric dimensions and related processing requirements of single turn overlap wave spring. Since there is no unified single turn overlap wave spring standard in China, the company produces or designs various single turn overlap wave springs according to customer requirements.

Maintenance method of overlap wave spring

The main method of maintenance for an overlap wave spring is visual inspection. This can be done by looking for signs of wear, damage, or misalignment. If any of these issues are found, the spring should be replaced.

It’s also important to make sure that the spring is properly installed and that it is not subjected to excessive loads or misalignment. This can be done by checking that the spring is installed according to the manufacturer’s instructions and that it is not being loaded beyond its rated capacity.

Additionally, it’s recommended to keep the spring clean, free of dirt, dust and debris.

In summary, the main maintenance method for an overlap wave spring is regular visual inspection, proper installation, and avoiding overloading and misalignment of the spring.

Application of single turn overlap wave spring:

A single turn overlap wave spring is an elastic element with several peaks and valleys. It is usually used in the occasions where the space is narrow, the load and deformation are not large, the spring stiffness is required to be small, and the axial preload needs to be applied. The uniqueness of Lisheng single turn overlap wave spring is that in terms of workload, the space occupied by Lisheng single turn overlap wave spring is relatively small. In fact, single turn overlap wave spring can reduce the size and weight of components by up to 40%~50%.

Processing technology of single turn overlap wave spring:

Lisheng Spring has the most advanced and precise spring equipment in China; the adjustment speed is fast, the production speed is fast, and for the difficult single turn overlap wave spring washer, all of them are formed at one time without additional processing. The company has professional spring online testing equipment, which can conduct 100% full inspection of springs. It is also equipped with spring high-precision CNC spring testing machines, precision projectors, tool microscopes, etc. to ensure that the quality of springs can meet customer requirements. The surface treatment methods of single turn overlap wave spring washer include bluing, phosphating, electroplating and electrophoresis.

Specifications of single turn overlap wave spring washer

According to the customer’s use conditions, select suitable materials to meet customer needs to the greatest extent. Commonly used materials are 17-7 stainless steel sus301 60Si2MnA, 50CrVA and various stainless steels.

Overlap wave springs are a type of wave spring that feature a series of overlapping wave-like coils. This design allows for a large amount of deflection, which makes them ideal for use in applications where precision is required. Additionally, they are able to withstand large loads without becoming permanently deformed.

What are the benefits of using overlap wave springs?

Wave springs are often used in place of coil springs, belleville washers, or other contact springs. They offer a number of benefits, the most notable of which are their ability to handle large loads and their low profile.

Wave springs are capable of handling much larger loads than coil springs, belleville washers, or other contact springs. This is due to their unique design, which allows them to distribute force evenly over a large surface area. This makes them ideal for applications where a large amount of force needs to be applied in a small space.

Wave springs also have a low profile, which makes them ideal for applications where space is limited. Their small size also makes them easy to install and remove.

What are the commonly used materials for wave springs?

- Springs and aluminum alloys, metal elements such as silicon, manganese, chromium, vanadium and molybdenum are often added to steel to make springs to increase the elasticity and fatigue limit of springs and make them resistant to impact.

- Large-scale wave springs are mostly processed by hot work, and the spring material is bound into a rod at high temperature. After high-temperature processing and forming, it is quenched in oil or water at about 780-850 degrees, and then tempered at a temperature of 400-500 degrees.

- Small springs, annealed in diameter first, processed by cold sitting, hardened and tempered after rolling, such as steel wire, piano wire or steel belt.

- The piano wire is made of high carbon steel (0.65 ~ 0.95%) with less impurities. When the diameter is often less than 1/4, it is drawn into a wire at room temperature. It has good mechanical properties, high tensile strength and toughness, and is an excellent coil spring material.

- Stainless steel wire is used in areas that are susceptible to corrosion, and high-speed steel and stainless steel can be used to withstand high temperatures.

- The carbon content of the oil tempering wire should contain manganese at 0.6-0.7%, and 0.6-1.0% is often used for coil springs.

- Common steel with 0.9-1.0% is commonly used for leaf springs, and chrome-vanadium steel and silicon-manganese steel are used for higher grades.

Advantages of Overlap Wave Spring:

- A space saving choice: smaller volume than round wire coil springs;

- Lighter weight and raw material usage than round wire coil springs;

- More operating heights, lower solid height than round wire coil springs.

Specification:

| Part No. | Operates in Bore Diameter |

Lears Shaft Diameter |

Load | Work Height | Free Height | Waves | Thickness | Radial Wall | Spring Rate | Open Mode |

| mm | mm | (N) | mm | mm | mm | mm | N/MM | |||

| LB-0035 | 9 | 6.86 | 25.8 | 1 | 1.5 | 3 | 0.2 | 0.81 | 52 | overlap |

| LB-0039 | 10 | 7.49 | 27.6 | 1 | 1.57 | 3 | 0.2 | 1.02 | 48 | overlap |

| LB-0043 | 11 | 8.46 | 29.4 | 1 | 1.83 | 3 | 0.2 | 1.02 | 35 | overlap |

| LB-0047 | 12 | 9.17 | 33.4 | 1 | 1.57 | 3 | 0.25 | 1.17 | 59 | overlap |

| LR-0050 | 12.7 | 9.91 | 31.12 | 1.27 | 2.16 | 3 | 0.2 | 1.02 | 35 | overlap |

| LB-0051 | 13 | 9.53 | 37.8 | 1 | 1.57 | 3 | 0.25 | 1.47 | 66 | overlap |

| LR-0062 | 15.88 | 12.19 | 44.45 | 1.27 | 2.41 | 3 | 0.25 | 1.47 | 38.85 | overlap |

| JBT-016 | 16 | – | 60-100 | 1 | 1.9 | 3 | 0.3 | 1.83 | – | overlap |

| LB-0063 | 16 | 11.28 | 44.5 | 1.57 | 2.29 | 3 | 0.25 | 1.98 | 65 | overlap |

| JBT-019 | 19 | – | 70-110 | 1 | 2 | 3 | 0.33 | 2.01 | – | overlap |

| LB-0075 | 19 | 14.28 | 53.4 | 1.57 | 3.05 | 3 | 0.25 | 1.98 | 35 | overlap |

| LR-0075 | 19.05 | 12.7 | 62.23 | 1.57 | 4.06 | 3 | 0.25 | 1.98 | 25.03 | overlap |

| JBT-022 | 22 | – | 80-140 | 1.2 | 2.3 | 3 | 0.42 | 1.9 | – | overlap |

| LB-0087 | 22 | 16.46 | 62.3 | 1.57 | 2.79 | 3 | 0.3 | 2.39 | 48 | overlap |

| LR-0087 | 22.23 | 15.75 | 71.12 | 1.57 | 3.3 | 3 | 0.3 | 2.39 | 41.13 | overlap |

| LB-0095 | 24 | 18.46 | 66.7 | 1.57 | 3.56 | 3 | 0.3 | 2.39 | 35 | overlap |

| LR-0100 | 25.4 | 19.81 | 80.02 | 1.57 | 4.06 | 3 | 0.3 | 2.39 | 32.2 | overlap |

| JBT-026 | 26 | – | 100-160 | 1.2 | 2.8 |